-

StevenCHN-TOP bieten sehr guten Service und die Produkte an, uns viel zu helfen

StevenCHN-TOP bieten sehr guten Service und die Produkte an, uns viel zu helfen -

S.N. SharmaCHN-TOP Maschine helfen mir, mein imprresion für chinesische Maschinen zu verbessern

S.N. SharmaCHN-TOP Maschine helfen mir, mein imprresion für chinesische Maschinen zu verbessern -

MikeBeste Produkte mit bestem Preis, CHN-TOP gut getan!

MikeBeste Produkte mit bestem Preis, CHN-TOP gut getan!

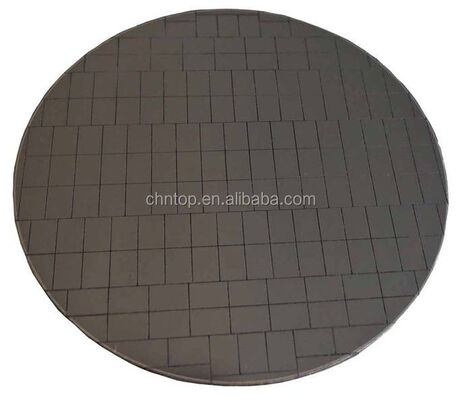

Granularity 10um PCD Blank Featuring High Thermalconductivity Thickness Varies By Specification Suitable for Cutting and Machining

Treten Sie mit mir für freie Proben und Kupons in Verbindung.

whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

Wenn Sie irgendein Interesse haben, leisten wir 24-stündige Online-Hilfe.

x| Thermalconductivity | High | Abrasive Resistance | Low |

|---|---|---|---|

| Model | 1.6-FS | Grit Size | 25um |

| Size | Customizable | Manufacturer | CTSTC |

| Surface Finish | Polished | Color | Typically Metallic Or Black |

| Hervorheben | 10um PCD blank for cutting,high thermal conductivity PCD blank,PCD blank thickness varies |

||

Product Description:

The PCD Blank manufactured by CTSTC represents a high-quality solution in the realm of advanced cutting materials, specifically designed to meet the rigorous demands of modern manufacturing and machining processes. As a fundamental component in the production of PCD Tools, this PCD Blank offers superior performance characteristics that ensure precision, durability, and efficiency in various industrial applications.

One of the standout features of this PCD Blank is its exceptional thickness, which varies by specification. This variability allows for a customized approach to meet specific machining requirements, enabling manufacturers to select the optimal thickness for their particular applications. The flexibility in thickness ensures that the PCD Blank can be adapted to a wide range of cutting tasks, from fine, detailed work to heavy-duty operations, making it a versatile choice for many industries.

Manufactured by CTSTC, a trusted name in the production of diamond materials, this PCD Blank benefits from the company’s extensive expertise and commitment to quality. CTSTC’s advanced manufacturing processes guarantee that each PCD Blank maintains consistent quality and performance standards, providing users with reliable and repeatable results. The manufacturer’s reputation for excellence underlines the product’s suitability for high-precision tooling applications.

Transparency is another critical attribute of this PCD Blank, which boasts high transparency levels. This characteristic is crucial for certain applications where visibility and light transmission through the material are essential. High transparency in the PCD Blank not only facilitates better observation during the manufacturing process but also contributes to the overall aesthetic and functional qualities of the finished PCD Tools.

The toughness of the PCD Blank is categorized as middle, striking a balanced compromise between hardness and flexibility. This middle toughness ensures that the POLYCRYSTALLINE DIAMOND material can withstand the stresses and strains encountered during cutting operations without compromising its structural integrity. This balance is vital for extending tool life and maintaining cutting performance under various operational conditions.

A polished surface finish is another defining feature of this PCD Blank. The polished finish enhances the material’s resistance to wear and tear, reduces friction during cutting, and improves the overall efficiency of the PCD Tools made from this blank. The smooth surface also contributes to better heat dissipation and reduces the likelihood of material buildup on the cutting edges, which can adversely affect tool performance.

POLYCRYSTALLINE DIAMOND, commonly abbreviated as PCD, is renowned for its hardness and thermal conductivity, making it an ideal material for cutting tools used in industries such as automotive, aerospace, woodworking, and electronics. The PCD Blank from CTSTC serves as the foundational element in the manufacture of PCD Tools, which are essential for precision machining of non-ferrous metals, composites, and abrasive materials. The use of PCD Blanks ensures that the resulting tools exhibit superior wear resistance, longer service life, and consistent cutting quality.

In summary, the PCD Blank by CTSTC is an indispensable material for producing high-performance PCD Tools. Its customizable thickness, high transparency, balanced toughness, and polished surface finish collectively contribute to its outstanding functionality and reliability. Whether used in intricate precision machining or demanding industrial cutting applications, this PCD Blank provides the essential properties required to achieve optimal tool performance and durability. Choosing this PCD Blank means investing in a product that embodies the advanced technological standards and quality assurance expected in today’s cutting tool industry.

Features:

- PCD BLANK with high transparency for superior performance

- Thickness varies by specification to meet diverse application needs

- Granularity of 10um ensuring precise and consistent quality

- High thermal conductivity for efficient heat dissipation

- Ideal for use in cutting tools designed for copper and wood

- Durable and reliable PCD BLANK suitable for various industrial applications

- Enhanced cutting efficiency with PCD BLANK materials

Technical Parameters:

| Thermal Conductivity | High |

| Toughness | Middle |

| Usage | Cutting Tools For Copper, Wood |

| Size | Customizable |

| Color | Typically Metallic Or Black |

| Grit Size | 25um |

| Transparency | High |

| Model | 1.6-FS |

| Thickness | Varies By Specification |

| Sharp | Round |

Applications:

The CTSTC PCD Blank, model number 1.0-10W, is an essential component widely used in various industrial applications where precision and durability are paramount. As a high-quality product with a grit size of 25um and a polished surface finish, this PCD Blank offers exceptional transparency and a smooth surface that enhances performance in demanding machining tasks. Its advantageous abrasive resistance is low, making it ideal for applications that require fine cutting and exceptional surface quality.

PCD Inserts and PCD Blanks like the CTSTC 1.0-10W model are predominantly utilized in the manufacturing of PCD tools. These tools are crucial in industries such as automotive, aerospace, woodworking, and electronics, where they are used for cutting, drilling, and machining non-ferrous metals, composites, and abrasive materials. The polished surface finish and high transparency of the CTSTC PCD Blank ensure excellent bonding with the tool substrate, resulting in increased tool life and superior cutting performance.

This product is especially suitable for precision machining occasions, such as high-speed turning, milling, and finishing operations that demand consistent accuracy and surface integrity. The CTSTC PCD Blank is packaged in a secure plastic box to protect it during transit and storage, supporting a minimum order quantity of just one piece, which offers flexibility to small-scale and large-scale manufacturers alike. With a supply ability of 1000 pieces per day and a delivery time of 5-10 days, CTSTC ensures timely availability for urgent production schedules.

When it comes to procurement, CTSTC offers negotiable pricing and convenient payment terms including TT, LC, and Western Union, catering to diverse customer preferences. The model 1.6-FS variant expands the range of options within the PCD Blank category, allowing clients to select the best fit for their specific tooling requirements. Overall, CTSTC's PCD Blanks are indispensable for producing high-performance PCD inserts and PCD tools that meet modern industry standards, providing reliable solutions for a variety of application scenarios.

Support and Services:

Product Technical Support and Services for PCD Blank include comprehensive assistance to ensure optimal performance and user satisfaction. Our support team provides detailed guidance on installation, configuration, and troubleshooting to help you effectively utilize the product.

We offer regular software updates and patches to maintain compatibility and enhance functionality. Our online knowledge base contains FAQs, manuals, and how-to guides for quick reference.

For advanced technical issues, our experts are available to provide remote diagnostics and solutions. We also offer training sessions and webinars to help users maximize the benefits of the PCD Blank product.

Additionally, warranty services and repair options are available to address any hardware concerns. Customer feedback is valued to continuously improve our support and service offerings.

Packing and Shipping:

Each PCD Blank product is carefully packaged to ensure maximum protection during transit. The blanks are individually wrapped and placed in a sturdy, cushioned box to prevent any damage.

Our packaging materials are chosen to be environmentally friendly while providing reliable protection.

Shipping is handled through trusted carriers with tracking available for all orders. We offer multiple shipping options to meet your delivery needs, including standard and expedited services.

Orders are processed promptly, and you will receive a confirmation email with tracking details once your PCD Blank product has been shipped.